The Air

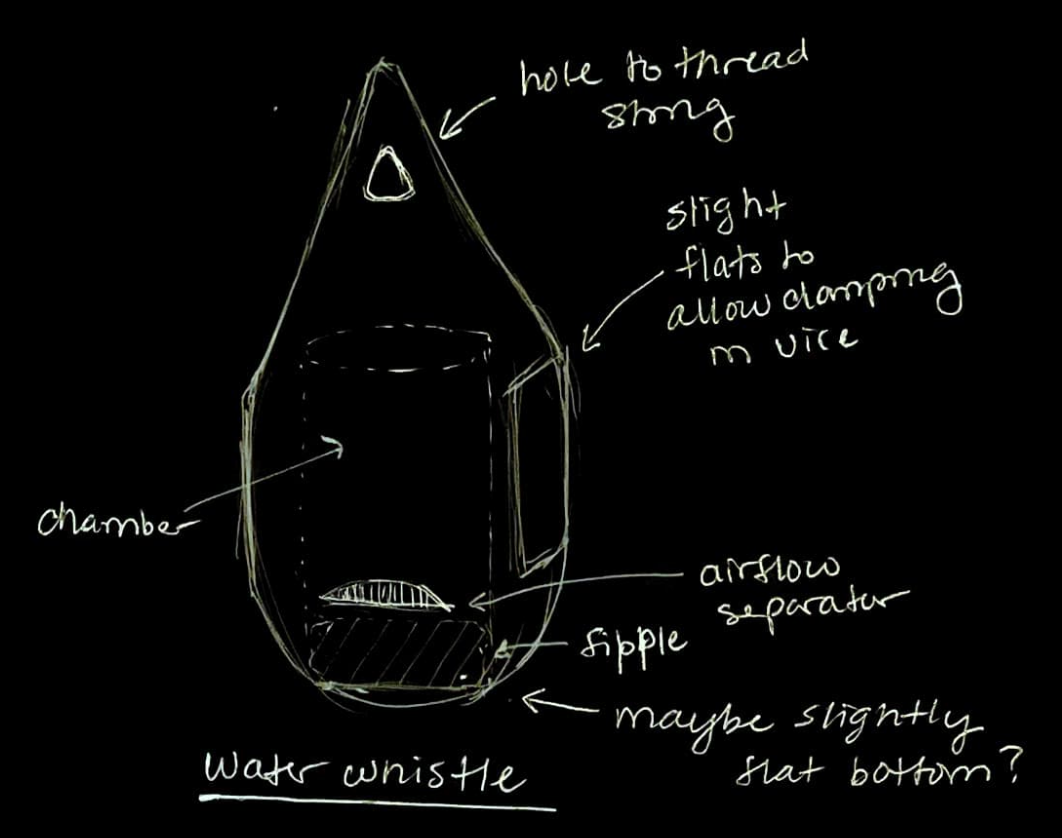

Droplet

Design and Prototyping Process

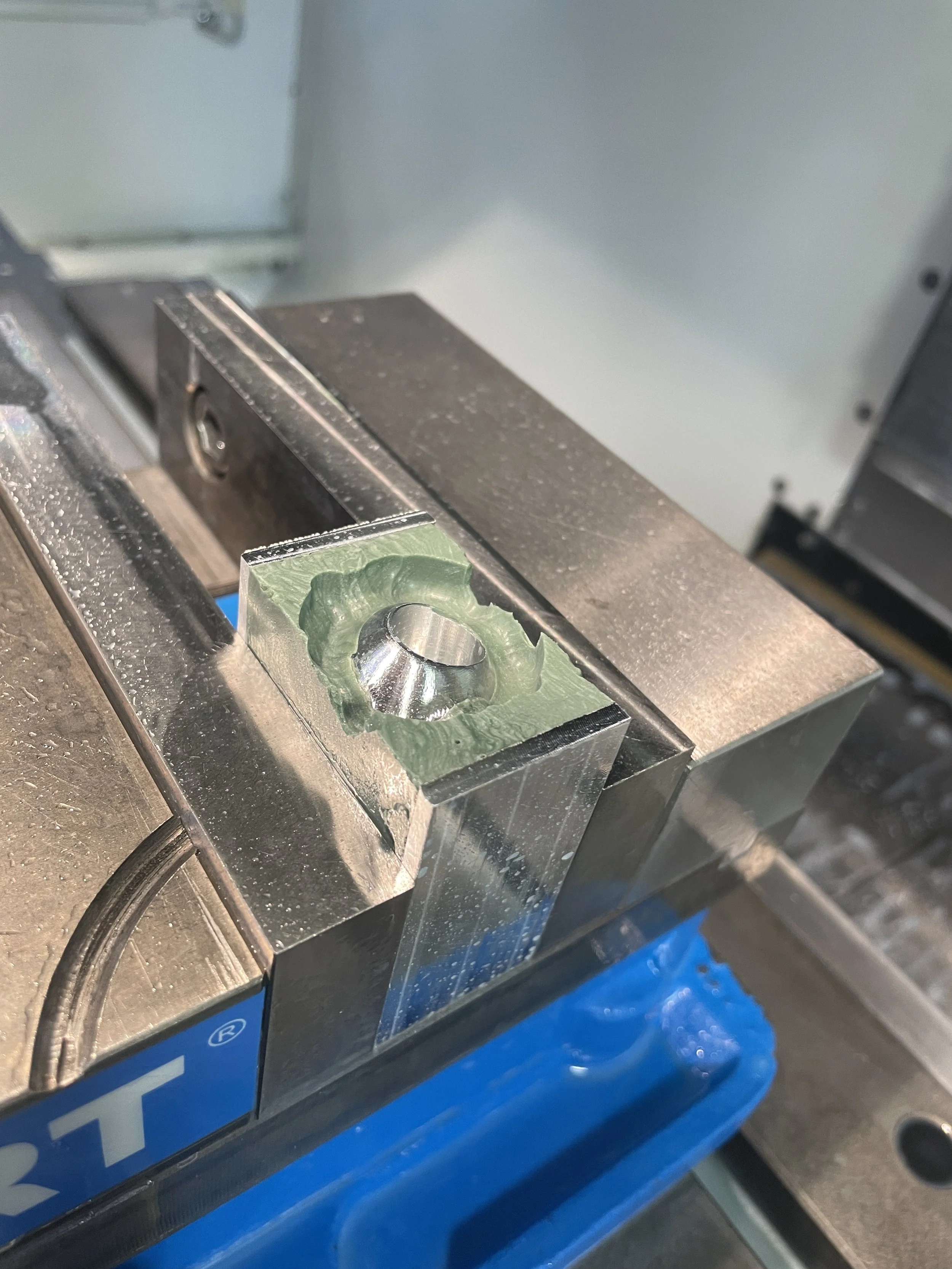

Manufacturing & Assembly

Outside of squaring stock and facing wax, the air droplet required three manufacturing setups.

Front Pocket

Whistle Cavity

The fipple was made on the manual mill/lathe and the whistle was assembled using an arbor press.

Back Pocket