ME 350: Disc Sorting Device

As part of Design and Manufacturing II (Winter 2022), myself and a team of 4 other students designed, built, and tested a four-bar linkage to sort colored discs. Our design broke the course record for the project, successfully sorting 18 discs in 13 seconds. At the conclusion of the semester, we presented our device at the U-M Mechanical Engineering Undergraduate Symposium

The Problem

Summary: Design a four-bar linkage that sorts colored discs onto the corresponding colored zones (regular or bonus) of the provided playing field.

Scoring: Points are awarded based on the accuracy of placement within zones. Speed is taken into account — devices capable of sorting 18 randomly ordered discs faster than 90 seconds gain extra points.

Constraints: Each team is provided a kit of linkage parts, which must be used. Custom parts may be machined, but these parts cannot be used in the construction of any of the four links. No part of the mechanism is allowed to touch the Sorting Area, only the Setup Area.

Design and Simulation

To hit all three bonus zones and maximize points, I designed a slider-crank four-bar linkage mechanism. This mechanism uses an electromagnet as its slider link — this component is also utilized for picking up and dropping discs.

The custom mounting bracket serves two purposes: constraining the electromagnet to slide over the desired zones and supporting the weight of the links as they cross over the Sorting Area.

The image to the right shows a SolidWorks render of our proposed initial design.

To ensure our crank slider would not reach a toggle point, the maximum desired transmission angle is 45°. Using SolidWorks, we determined our design had a maximum transmission angle of 33.88°.

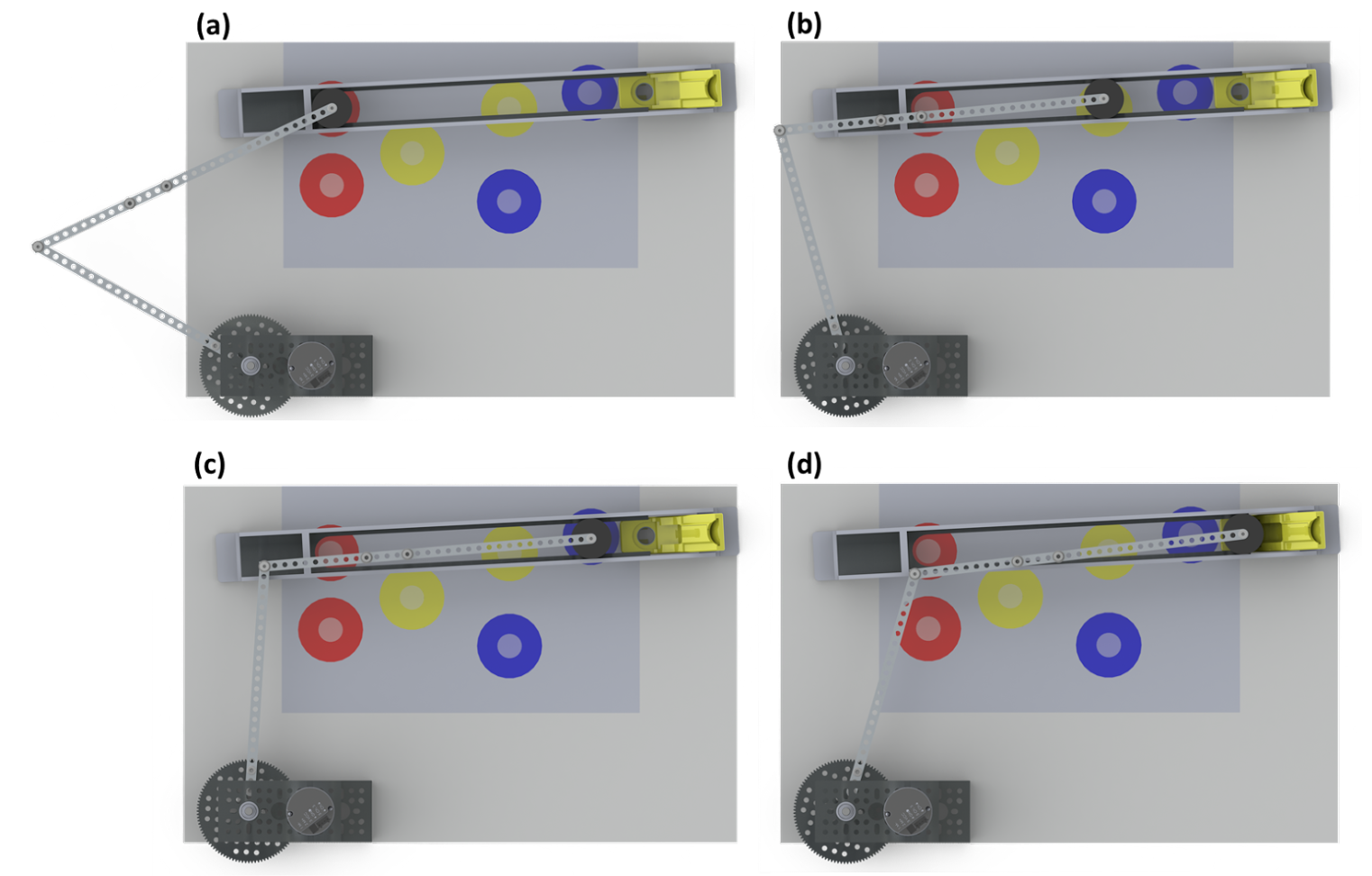

Using ADAMS, we simulated the motion of our mechanism, measuring linkage power (Fig. a), angular velocity (Fig. b), angle (Fig. c), and input link torque (Fig. d).

Prototyping and Machining

Our custom slide rail was prototyped using a Prusa MK2 FDM 3D Printer (left), then redesigned for conventional machining (right) and handmade on a mill (below).

Electronics and Control

To actuate our linkage, we used a DC motor and encoder, controlled using an Arduino Uno and H-bridge. A color sensor was placed inside our disc feeder to determine which disc was being picked up, and an electromagnet transported the disc to its destination.

A PID controller was implemented and visually tuned using the Ziegler-Nichols method to accurately drop discs.